Description

By: Matt Joseph . - CT-SA196P

Description

- Choose the highest quality material

- Form crowns and compound curves

- Fabricate custom and replacement body panels

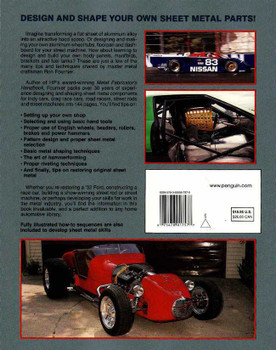

Creating door skins, fenders, hoods, and a variety of other components from sheet metal is a crucial skill for building hot rods, restoring many classic cars, and fabricating parts for competition cars. While many specialized and expensive tools may be used to form sheet metal into functional and finished parts, simple and affordable tools, such as metal working hammers, dollies, anvils, and shot hags, can be used to create parts with complex curves and crowns for many projects.

Automotive Sheet Metal Forming & Fabrication provides instruction and information for you to become a skilled metal craftsman. This book shows the enthusiast how to design and fabricate with inexpensive and simple tools, as well as how to fabricate parts using more specialized tools, such as an English wheel. Author Matt Joseph explains how to use a wide range of specialized metal working tools and equipment, including wire welders, metal shears and brakes, planishing hammers, and shrinker/stretchers. He shows how to work steel and aluminum, and how to select the right metals for fabricating various kinds of parts. This book also discusses how to determine elastic limits as well as how to shrink and expand metal, heating and annealing, and many other metal working techniques. this book contains useful instruction and information for metal workers, from novice to intermediate and even advanced, on how to apply force and use good judgment, thorough planning, close observation, creativity, and restraint to create almost any metal part. With this book, simple to complex fabrication and metal forming tasks are within the reach of adept enthusiasts.

Other Details